As renewable natural gas (RNG) gains momentum in the energy sector, the need for specialized RNG odorization systems has never been greater. The GPL 750 RNG is at the forefront of this revolution, offering unique advantages that make it the ideal choice for RNG producers.

The Rising Importance of RNG Odorization

With the rapid growth of biogas and renewable natural gas (RNG or biomethane) production, the demand for specialized odorization systems has skyrocketed. These systems ensure RNG’s safe distribution and use by adding a distinctive odor to the otherwise odorless gas.

The RNG Production Process

Biogas undergoes a rigorous upgrading process to remove CO2 and trace elements, transforming it into biomethane (RNG) that matches the quality of conventional natural gas. This upgraded gas can then be seamlessly integrated into existing natural gas distribution networks.

Key Players in RNG Interconnection Projects

Typically, RNG interconnection projects involve two primary parties:

- Producer/Developer: Responsible for gas recovery, processing, and meeting pipeline requirements. This could be a digester owner, process developer, or local utility company.

- Pipeline Operator: This is usually a local distribution company (LDC) that transports the gas and may purchase it or deliver it to a third-party buyer.

The GPL 750 RNG: A Game-Changer in RNG Odorization

The GPL 750 RNG odorizer has emerged as a leading solution for addressing the unique challenges of RNG odorization. Let’s explore the five key advantages that make it the top choice for biomethane producers:

1. User-Friendly Design and Operation

For many RNG producers, particularly those new to the gas industry, the complexities of odorization can be daunting. The GPL 750 RNG tackles this challenge head-on:

- Simple, five-component design

- A quick learning curve for operators

- Comprehensive training options (on-site or attend an operator training class at the factory)

- Rapid troubleshooting (typically resolved within 30 minutes)

- Minimal odorant contact is required for maintenance

2. Seamless Stop & Start Capability

2. Seamless Stop & Start Capability

RNG production often faces intermittent flow issues due to various factors, such as fluctuating demand or gas quality concerns. The GPL 750 RNG excels in handling these challenges:

- Self-priming system

- Manages extended periods of no flow without intervention

- Automatic reactivation when gas flow resumes

- Differential pressure-driven odorant injection

3. Precision Odorization Control

Over-odorization is a significant concern for RNG pipelines, especially those with low flow rates. The GPL 750 RNG offers advanced features to prevent this issue:

- Real-time odorant injection rate monitoring

- Customizable alarm setpoints

- Integration with plant or gas company RTU via digital outputs or Modbus

- Minimizes the risk of over-odorization and downstream problems

4. Round-the-Clock Expert Support

GPL Odorizers understands the critical nature of odorization systems and provides comprehensive support:

- 24/7 service hotline

- Expert assistance for operational queries and troubleshooting

- Coordination with authorized service providers for on-site support when needed

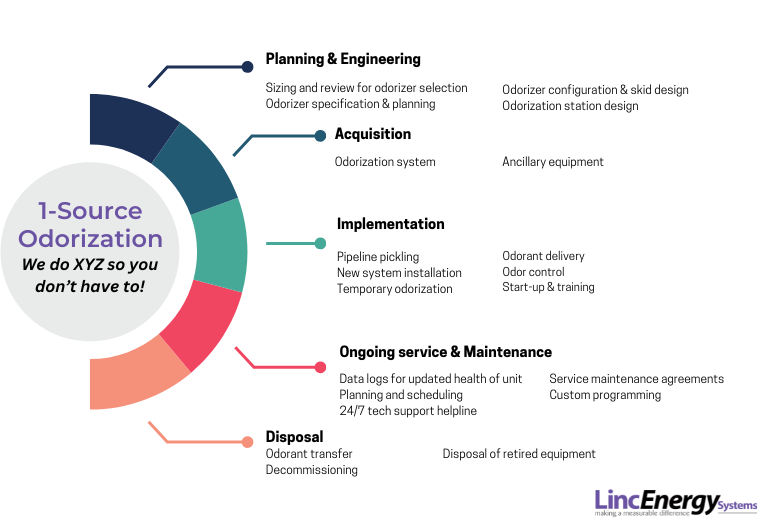

5. Comprehensive 1-Source Odorization Solution

Through a partnership with Linc Energy Systems, GPL Odorizers offers a turnkey solution for RNG producers:

- Complete project management from design to decommissioning

- Customizable options to minimize or eliminate direct odorant handling

- Ideal for producers unfamiliar with odorization complexities

The Future of RNG Odorization

The Future of RNG Odorization

As the renewable energy sector continues to evolve, the importance of efficient and reliable odorization systems for RNG will only grow. The GPL 750 RNG is at the forefront of this technological advancement, offering a solution that combines simplicity, reliability, and precision.

For RNG producers looking to ensure the safety and compliance of their gas while minimizing operational complexities, the GPL 750 RNG represents the future of odorization technology. Its user-friendly design, adaptability to irregular gas flows, and comprehensive support system make it an invaluable asset in the rapidly expanding RNG market.

By choosing the GPL 750 RNG, producers are not just investing in equipment – they’re partnering with industry leaders to drive the safe and efficient growth of renewable natural gas infrastructure.

Ready to revolutionize your RNG odorization process? Contact us today to learn how the GPL 750 RNG can benefit your operation and contribute to a cleaner, safer energy future.

What to Learn More?

- Download infographics: 5 Advantages of GPL RNG Odorizer.

- Download product sheet: GPL 750 RNG product sheet.

- Download service sheet: 1-Source Odorization

The GPL 750 RNG excels in odorizing biogas, biomethane, and renewable natural gas (RNG). Because of its simplicity and service options, the GPL 750 RNG is the prime choice for producers/developers not entirely familiar with the complexity and regulations of odorization.